PCB Surface Coating Functions and Selection Principles

Copper in PCBs oxidizes, causing solder defects and reducing product life. Surface coatings like HASL, OSP, ENIG, and ENEPIG prevent this, ensuring solderability and reliability. Choosing the right coating based on application needs significantly improves the quality, reliability, and lifespan of products.

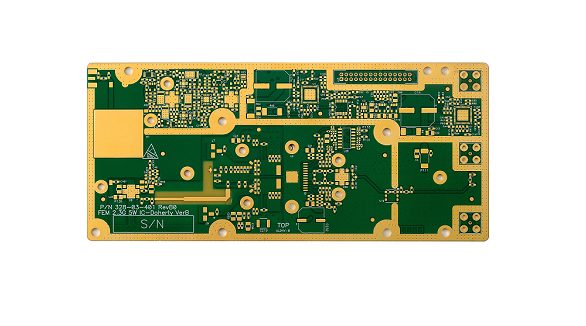

Copper is used for conducting routes on printed circuit boards (PCBs) because of its excellent electrical conductivity and strong physical characteristics. Unfortunately, copper is highly reactive and oxidizes quickly in air to form a thin solid oxide layer at the surface, which cause defects in the solder joints and hence reliability issues with the product, thereby reducing the life of a product. Therefore, protection from copper oxidation is essential. This requirement has brought about several surface coatings, which should withstand heat and be solderable. This article explains the functions, types, and principles of selection of surface coating on PCBs.

What is PCB Surface Coating?

Why PCB Surface Coating is Important?

These surface finishes are applied to the copper pads of a PCB to prevent oxidation and contamination while retaining solderability. Copper is an excellent conductor and inexpensive; hence it is used as a conducting material for PCBs. Its high degree of reactivity means it easily forms an oxide layer, leading to defects in the solder joints and significantly reducing the reliability and shelf life of the product.

Statistics indicate that about 70% of the defects in a PCB are due to solder joints, and there are two major reasons for this:

Oxidization and Contamination: Oxidation and contamination of the pads on a printed circuit board will lead to incomplete soldering or cold solder joints.

Diffusion and Inter-Metallic Compounds (IMCs): Diffusion between silver and copper, and the formation of IMCs between tin and copper at the interface, make it loose and brittle.

Hence, a solderability or isolation protective layer on the copper surface is necessary to reduce or prevent these defects.

Requirements for PCB Surface Coatings

The following are the characteristics desired of the surface coating on a PCB pad:

Heat Resistance

The coating needs to prevent the oxidation of the surface of the PCB pad during high-temperature soldering and enable solder reverse contact to take place with copper directly. The melting point of the coating should be close to or lower than that of solder, while its thermal decomposition temperature is much higher.

Coverage

The coating shall provide good coverage of the copper pad surface such that no oxidation or contamination at all may occur before and during soldering. It should also not drift, decompose, or float on the solder joints and represent all solder adhesion onto the pad.

Residue

The residue left on either the pad or solder joints after soldering should be kept as minimal and easily removable to prevent any potential kind of hazard.

Corrosivity

The coating should not cause corrosion of the substrate or metallic layers of the PCB during the post-soldering process.

Environmental Considerations

Environmental consideration is gaining much importance. The effluents generated during application and related cleaning processes should have easy handling and be ecologically friendly.

Types of PCB Surface Coatings

Based on Manufacturing Technology

The PCB surface finishes depend on their manufacturing processes, and according to this, including:

Surface Coating

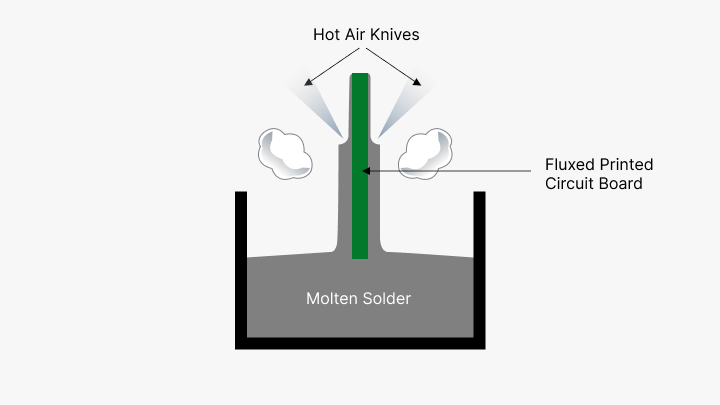

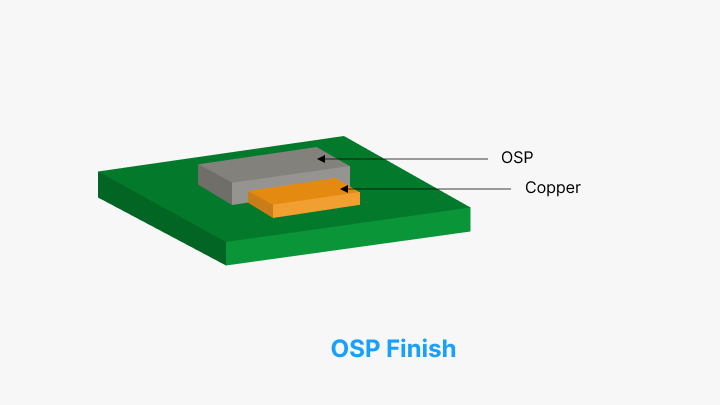

Physically adds a thin, heat-resistant, and solderable coating to the copper surface. Examples include HASL and OSP.

|  |

|---|

Metal Coating

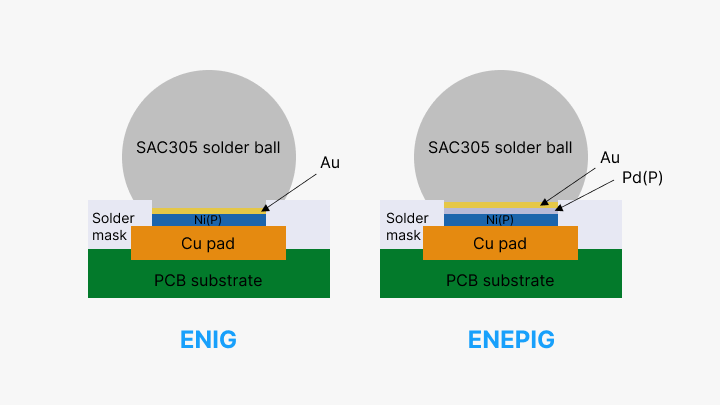

Consists of electroless plating and electroplating to create a metal coating over the copper pad, which is heat-resistant and solderable. Examples include ENIG and ENEPIG.

Based on Application Effects

According to their application effects, the surface finishes can be divided into three categories as follows:

Soldering flux on the coating of the isolating layer

Allows the solder to float on the surface under high-temperature soldering; however, IMCs can form at the interface, increasing defect risks.

Soldering flux on the metal coating of the diffusion layer

Designed to eliminate IMCs but can cause diffusion and brittleness, which may result in defects in circuits.

Soldering flux on the isolating layer of the metal coating

Avoid the contact of solder with copper and hence it will not form any IMC or normally diffuse the metal, thus providing an increase in reliability to the part.

Choosing the Correct Type of PCB Surface Coating

This PCB surface coating selection may have an impact on solderability, reliability, and shelf life. The decision is based on the application and its requirements.

For a General Application

Coatings like HASL or OSP, which allow soldering flux to adhere without an isolating layer, are appropriate for use in consumer electronics and industrial devices.

For High-Reliability Applications

In high-reliability and long shelf life applications, it is recommended to use surface coatings in which the soldering flux adheres to an isolating layer itself, like ENIG or ENEPIG, in fields of medical devices, transportation, military, and aerospace.

Knowing the importance, types, and selection criteria for PCB surface coatings will significantly improve the quality and reliability of products in a variety of industries.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Selecting the right PCB surface finish, from options like HASL, ENIG, ENEPIG, and OSP, is crucial for preventing oxidation, ensuring solderability, and meeting reliability standards.

The trend towards lead-free PCB manufacturing comes due to the EU's ROHS directive, which requires compliance to the limits on the content of lead. Compliance with lead-free is achieved by different surface finishes such as ENIG, ImAg, ImSn, and OSP—all with their different pros and cons. This paper compares these finishes to help choose the best for specific PCB applications.

The article insinuates the need for Organic Solderability Preservatives on printed circuit boards. OSP can adsorb onto the copper surface to prevent oxidation and moisture and can easily get washed out by soldering. It is easy to manufacture an OSP, which is environmentally friendly and not expensive, thus becoming one of the most popular surface finishes today.